VCP Pressure Relief Valves are the last resort when abnormal pressure conditions endanger the silo structure. This is why sudden excess or suction pressure inside the silo must be dealt with instantaneously. Even though ideally a Pressure Relief Valve should never have to go into action, it must be efficient and reliable if needed.

With hundreds of thousands installed worldwide, VCP Pressure Relief Valves have given evidence of being totally reliable under most different conditions.

For applications in the food industry a version compliant with European Regulation (EC) No. 1935/2004 is available.

TECHNICAL SPECS

Description

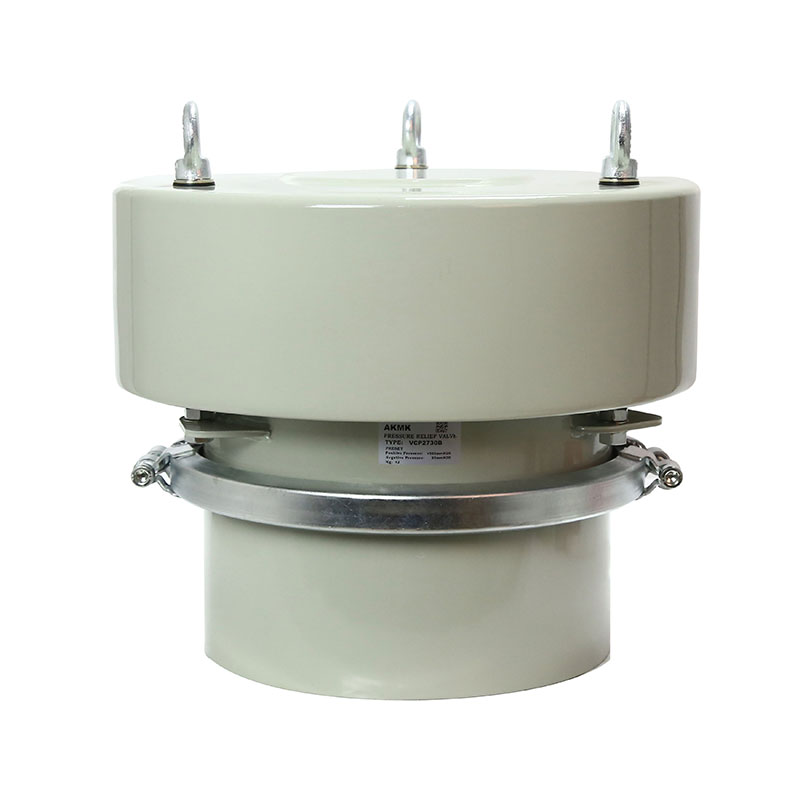

VCP Pressure Relief Valves consist of a cylindrical casing with a bottom flange to be connected with a spigot welded on the silo roof, a disc shape inner steel lid for negative pressure operation held in position by a central spring rod, an outside steel ring for excess pressure kept in position by three spring rods, gaskets, and a weather protection cover.

Function

Helical springs keep the valve lids closed when the pressure value remains within the preset limits. The three outside spring rods keep the external ring-shaped lid firmly closed as long as the force generated by the pressure inside the silo does not overcome the spring force. Once the pressure exceeds the pre-set value the lid is pushed up and pressure can escape. The smaller lid covers the central circular opening of the external lid from below. It is held in the middle by a single spring rod and is pressed onto the external lid by the normal air pressure inside the silo. In the event of suction pressure the spring is compressed and allows the lid to drop. The air entering the silo from outside ensures rapid pressure balance and pushes the central lid back up into "closed" position.

For applications in the food industry a version compliant with European Regulation (EC) No. 1935/2004 is available.

Features

Two sizes available

Flow rate: up to 13,000 m3/h (7,650 cfm)

Painted carbon steel or 304 stainless steel casing

Stainless steel weather protection cover

Mechanical set-up for inductive signalling sensor

Preset for maximum negative pressure of -0.005 bar (-0.07 psi) and maximum excess pressure of 0.05 bar (0.72 psi)

Benefits

Lightweight design and reduced overall dimensions for extremely comfortable handling

Easy to fit

Quick maintenance

Options

ATEX-certified version

Compliance with European Regulation (EC) No. 1935/2004

Optionally different settings available

Inspection hatch

Inductive sensors

Bird net

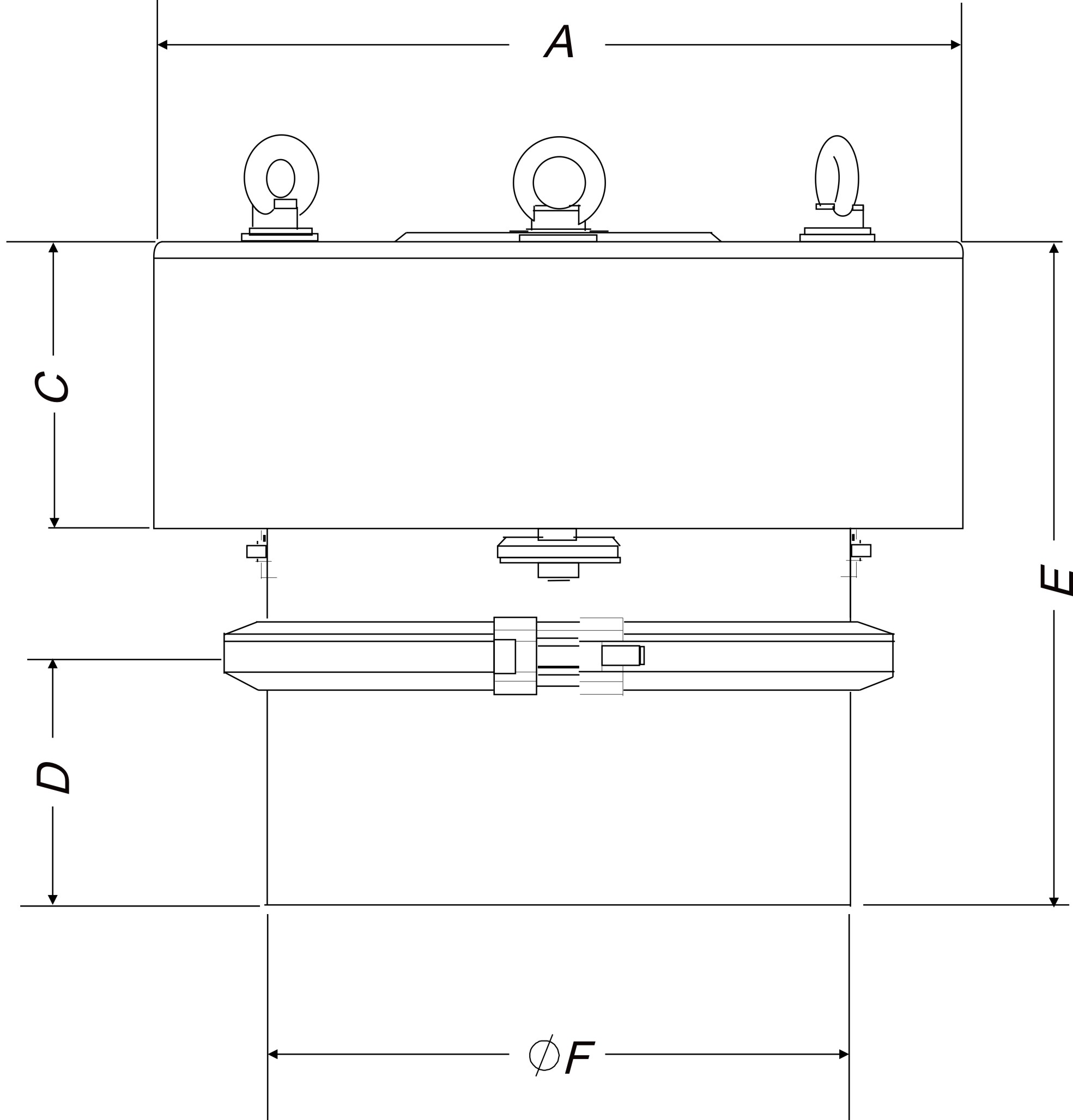

Item # | Body Material | (A) Inch | (B) Inch | (C) Inch | (D) Inch | (E) Inch | (F) Inch | Weight (Kg) | |

VCP.273 |

| Carbon Steel | 15.75 | 14.02 | 4.92 | 4.72 | 12.80 | 10.75 | 12 |

VCP.273.1 |

| Carbon Steel with Stainless Steel Cover | 20.67 | 18.43 | 6.89 | 4.72 | 15.75 | 10.75 OD | 12 |

VCP.273.2 |

| 304 S S Stainless Steel | 20.67 | 18.43 | 6.89 | 4.72 | 15.75 | 10.75 OD | 12 |

VCP.273.3 |

| 316 S S Stainless Steel | 20.67 | 18.43 | 6.89 | 4.72 | 15.75 | 10.75 OD | 12 |